PRODUCTS

PLUG-IN DRIVE SECTION IN FAN APPLICATIONS

Group: drive+ motor+ fan

0,75 KW – 3 KW / 110 – 460 V

INTERNAL FILTER

Control for. asynchronous – synchronous – brushless sensorless motors

Group: motor mechanically coupled to the fan.

The whole is driven by a simple inverter and by an external control.

Often the inverter is incorporated in the “motor + fan” group , in order to have a compact group called PLUG-IN.

System control is usually external.

SYSTEM:

DRIVE+MOTOR TORQUE

FOR BIG FAN CONTROLS : DIRECT DRIVE

0,75 KW – 7,5 KW / 380 – 460 V ac

Realization of drives suitable for “motor+ fan” groups specialized for final applications in order

to realize systems with:

⦁ smaller dimensions than the previous solutions

⦁ lower costs or in any case simpler systems to install

⦁ maximum efficiency of the groups to reduce consumption

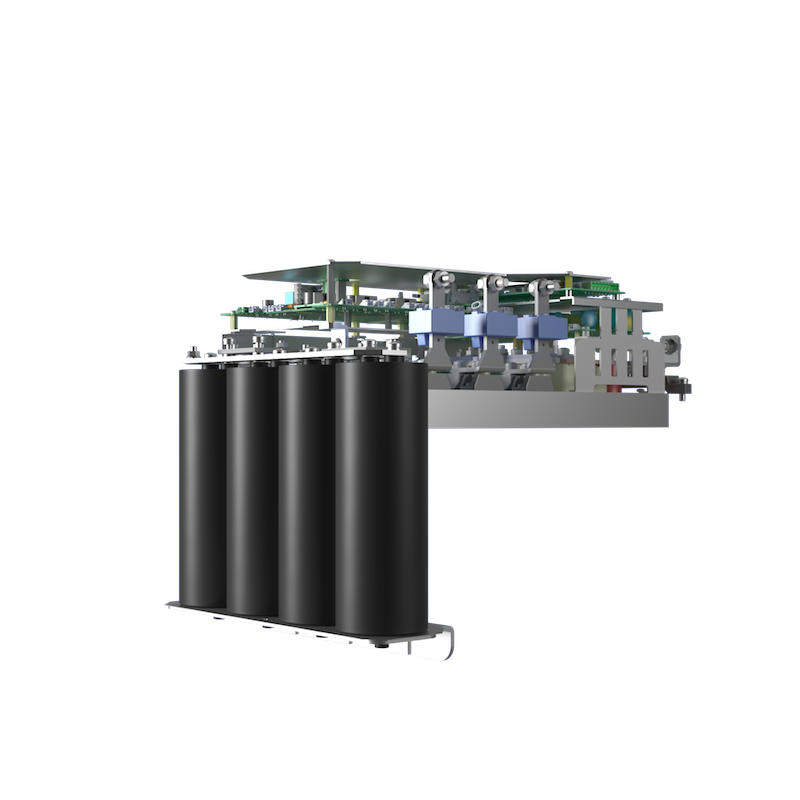

DRIVE POWER SECTION FOR ASYNCHRONOUS AND SYNCHRONOUS BIG ELECTRIC MOTOR CONTROL

50 – 350 KW / TRIFASE: 460 V AC

Possible application: integrated drive on screw compressors for chillers or other external solutions.

Heat dissipation is achieved by compressor gas on a custom plate.

The control and status of the inverter can be done via digital and analogical inputs or serial bus communication.

Serial connection via Modbus (RTU) rs485 or other programming tool provides access to system control.

IP54 INVERTER FOR ELECTRIC MOTOR

Power supply:

230- 400V SINGLE-PHASE-THREE-PHASE

Range: 1KW- 2,5 KW – 50-60 Hz IP54

SYSTEM WITH UNIVERSAL ADAPTER/HOOK FOR ALL ASYNCHRONOUS MOTORS

DX100

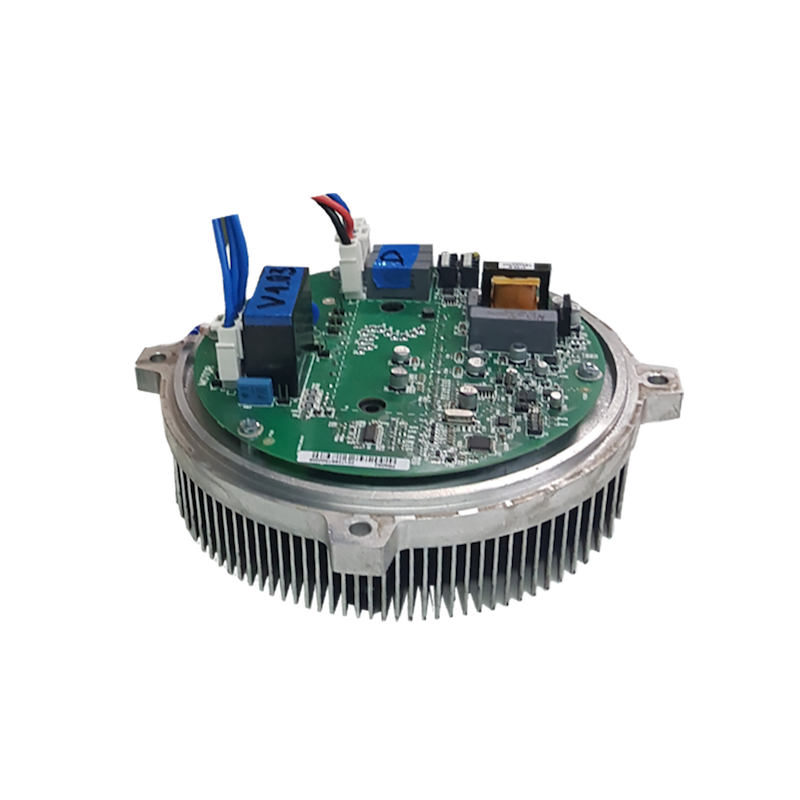

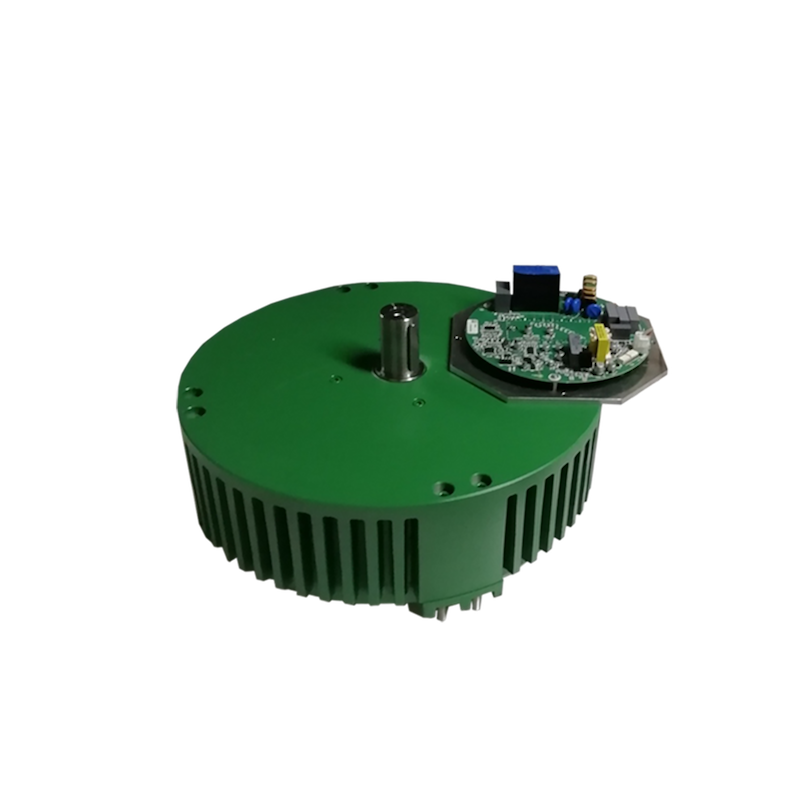

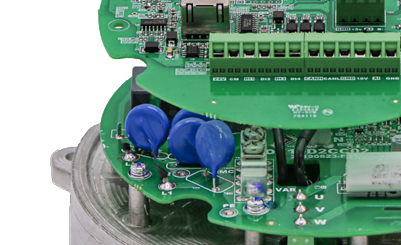

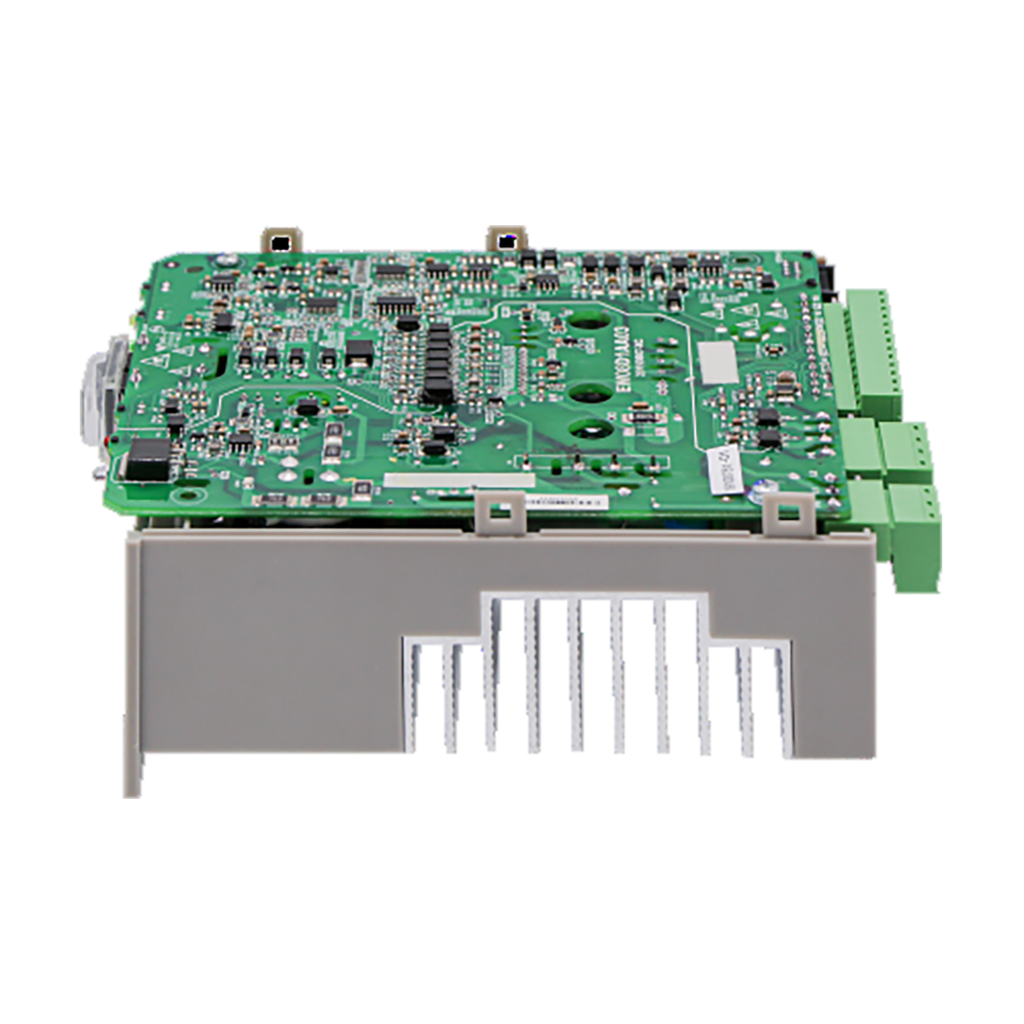

COMPACT INTEGRATED AC DRIVE FOR EC MOTOR , mountable directly on the bottom of the electric motor

.

Control for high-speed motor AC, PM, BLDC.

Dimensions: 185.3* 186.6* 121.2mm – 0.75Kw, 4.5A,

Self-cooling

Built-in EMC filter

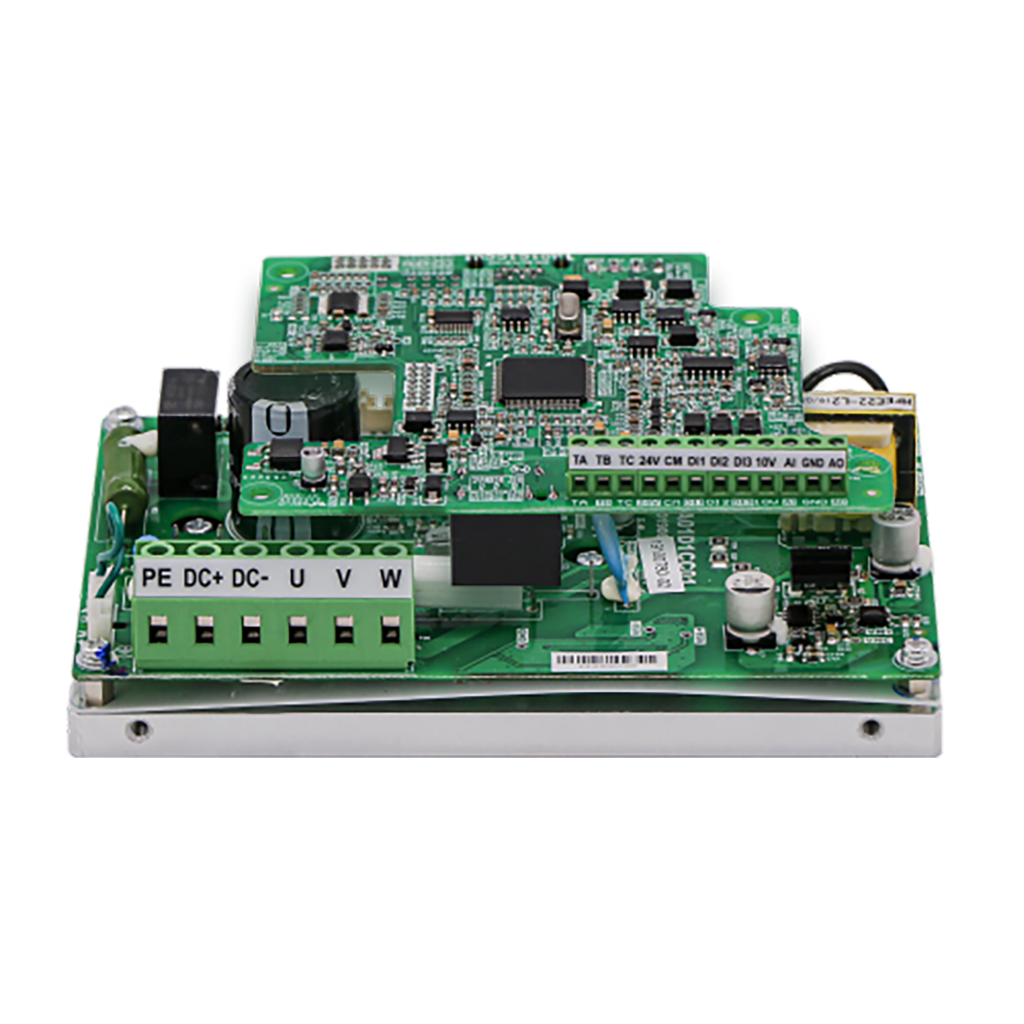

TA100

ac drive for ventilation on high speed train

⦁ DC input, AC output, SVC control for PM motor

⦁ DC77V – 137V input, NOMINAL FREQUENCY 175Hz

⦁ Output; 3ph 0- 96V

⦁ Self-cooling, overload 150% 60sec

⦁ Modbus, built-in EMC filter, IP25

EW800

Compact inverter for textile machines.

Simple, easy to use, special software for textile applications.

⦁ AC and PM motor control, PM

⦁ Size: 80* 138* 172mm – 0.2Kw, 1.5A

⦁ Self-cooling

⦁ Modbus, EMC filter as standard

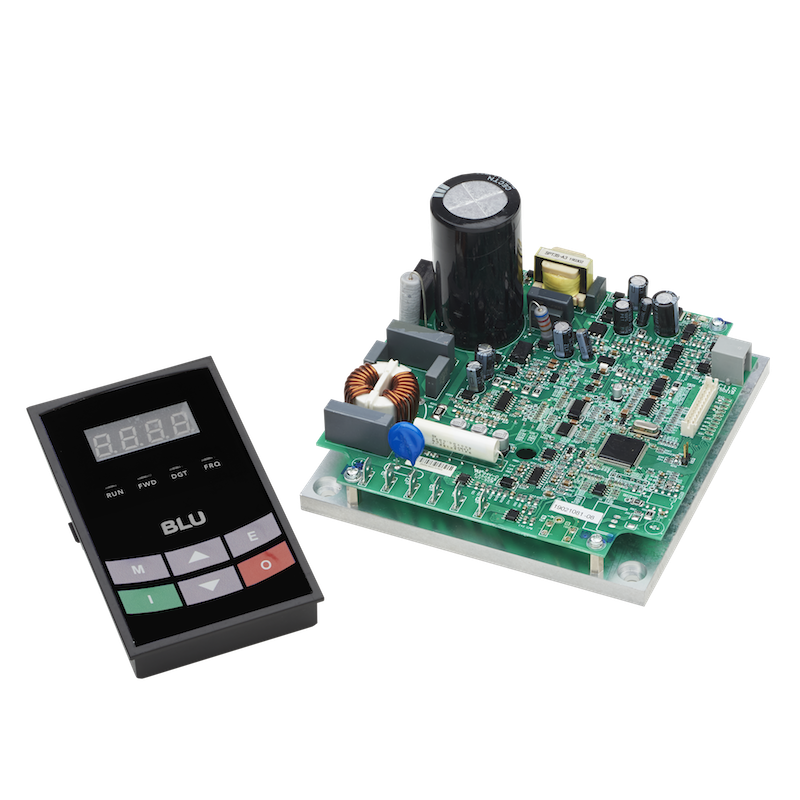

Inverter IP00 SINGLE CARD E800

Same technology as E800 model of universal converters widely used for V/F control of pump and fan.

⦁ SVC control for AC, PM, BLDC motor

⦁ 0.75kW, 4.5A, 220- 460V +/- 15%.

⦁ external remote keypad

⦁ Modbus

⦁ EMC filter

⦁ Standard brake unit

Dedicated IP66 solutions

Expansion of the modular EP66 drive enclosure:

Stainless steel housing for various customer-specific add-on components such as:

⦁ Sinusoidal filters

⦁ Chokes, selective protection/motor bypass switches

⦁ Easy to mount, EP66 degree of protection

⦁ to order according to customer specifications, even for small quantities

Motor – Pump – Inverter

Simple installation unit, easy to configure, pump intercommunication via MODBUS.

Efficient algorithm for pressure, flow and level control.

Various options are available:

⦁ fieldbus integration

⦁ W-LAN

⦁ SMS alert