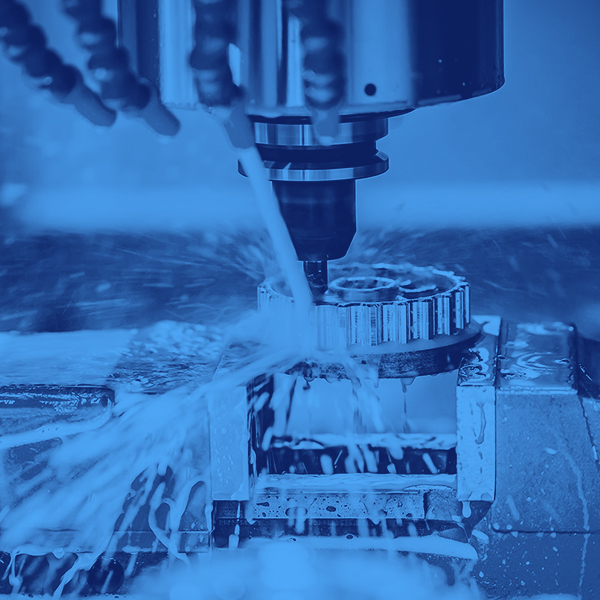

APPLICATION

MOTION CONTROL FOR INDUSTRIAL AUTOMATION

The term MOTION CONTROL is used to define the set of electrical drives for speed control of AC, DC and brushless motors.

The systems we develop are used in the most modern industrial automation systems.

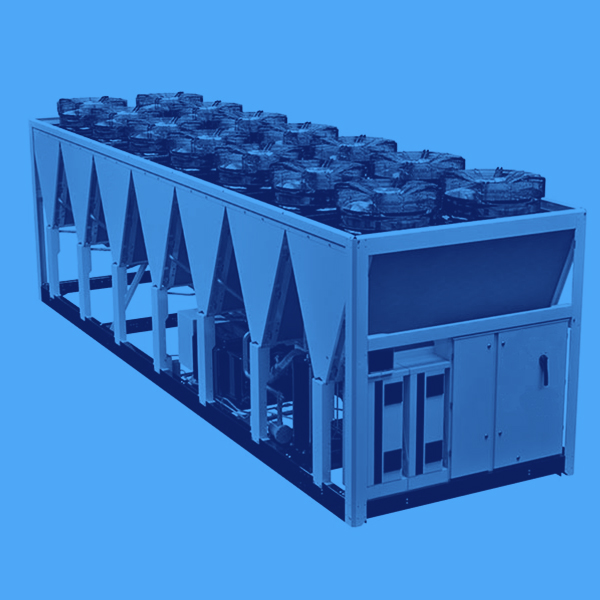

HVAC&R

HVAC&R stands for “HEATING, VENTILATION, AIR CONDITIONING AND REFRIGERATION” and includes all heating, ventilation, air conditioning and cooling systems.

HVAC&R systems aim to ensure comfort in the tertiary and residential sectors (e.g. homes, hotels, offices and stores) or in contexts with high manufacturing standards (e.g. paper production industries, chemical processes).

In the context of heat pumps, the use of our inverters ensures particularly high seasonal performance, both in hot and cold.

RENEWABLE AND ALTERNATIVE ENERGIES.

Every day, the carbon dioxide we produce is released into the earth’s atmosphere, causing the so-called “global warming effect”.

An answer to this problem is to replace today’s technologies with alternatives that have equal or better performance, without emitting carbon dioxide: THE SO-CALLED ALTERNATIVE ENERGY

- SOLAR

- WIND

- HYDROELECTRIC

- COGENERATION

PUMPS

Super compact booster units: Motor-Pump-Inverter.

Simple and easy installation, pump intercommunication via MODBUS.

Efficient algorithm for pressure, flow and level control.

Various options are available: fieldbus integration, W-LAN, SMS alert.

ADVANTAGES:

⦁ Current is proportional to motor speed.

⦁ Pressure is proportional to the square of the motor speed.

⦁ Power is proportional to the cube of the motor speed.

⦁ The current variation is obtained by the variation of the motor speed: in this way the power absorbed by the motor is much reduced.

⦁ Energy expenditure is reduced by approximately 60% depending on the load conditions.

⦁ Savings on installed energy

⦁ Reduction in peak current and voltage drop.

⦁ Elimination of water hammering

⦁ Noise reduction

⦁ Load rephasing

FANS

CONTROL TYPES

⦁ V/Hz control for AC motors

⦁ Sensorless control for brushless motors

⦁ Sensorless vector control for AC motors

⦁ Temperature

⦁ Pressure

⦁ Differential pressure sensor

⦁ 10 V/ 4- 20 mA

⦁ Air velocity sensor

⦁ CO2 sensor – Humidity sensor

⦁ Air current control

⦁ Master-slave operation

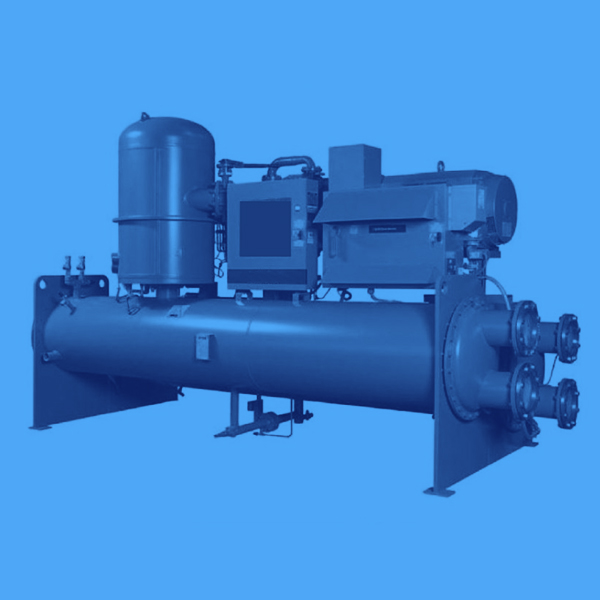

COMPRESSORS

We develop technologies that allow the modulation of the speed of the compressor motor and, consequently, allow to regulate the cooling capacity of the machine, managing at best the load variations.

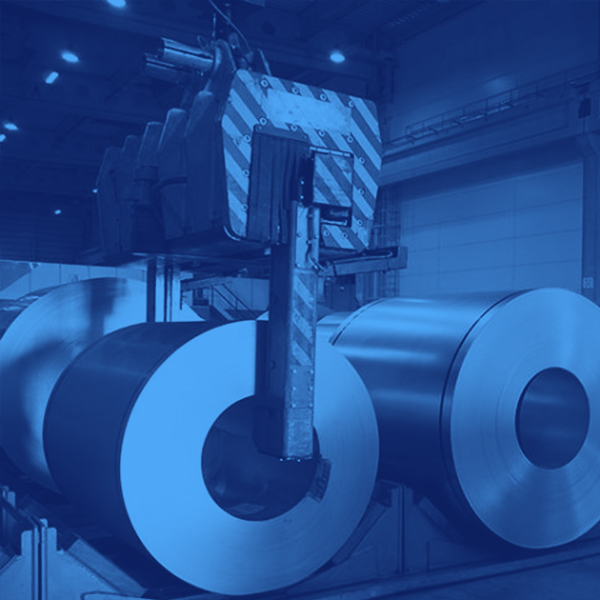

METAL

We take advantage of the versatility of drives, using PLC applications to provide precision control and maximum dynamic performance and thus obtain the best possible control of speed, voltage or positioning depending on the activity required.

LOGIC LAB programming software allows the company to perform its own programming reducing start-up and project times.

Last but not least, COST (reduced programming, wiring and assembling times) and ENERGY SAVING.

Examples of control modes:

Drives provide servo control in press feed units and cut-to-length lines;

-drive in closed loop AC mode in cut-to-length lines

-in open loop AC control in a variety of applications from conveyors to other material handling tasks.

ROPEWAYS

The control unit is the same for Afe and Inverter (only the software is different).

Possibility to obtain only the single units (power and regulation).

The system complies with the SAFETY TORQUE OFF standard.

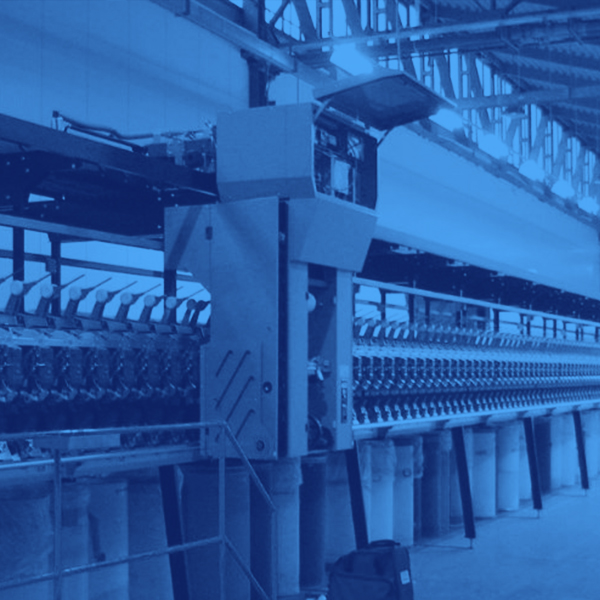

TEXTILE

TEXTILE MACHINES FOR YARN FINISHING AND SPINNING

A tunnel system with common power bus has been realized for the control of textile machines.

The rotating motor frame is fully automatic to ensure high flexibility, energy saving and allow frequent machine reconfigurations for dynamic production change.

The machine uses different types of motors:

-Synchronous with or without speed sensor

-Brushless motors

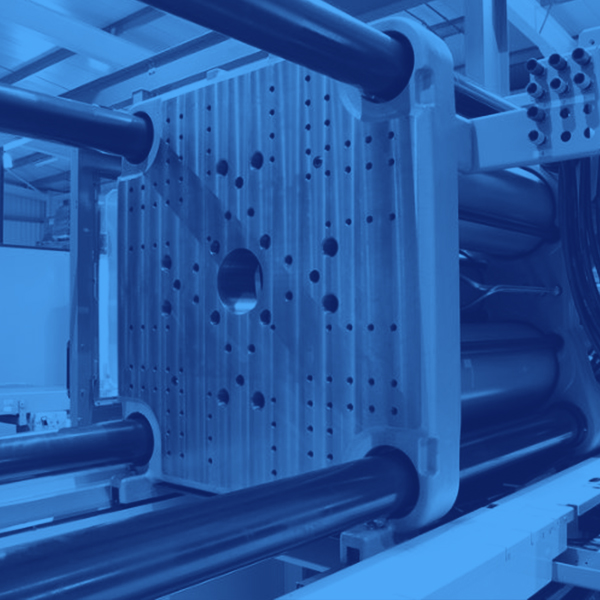

PLASTIC

System specially designed for injection molding machines.

The guidance system controls the flow and pressure limit with PID function.

The hybrid solution: pump and screw control.

The driving system controls the management of speed profiles: the digital network between servo pumps, drivers and proportional distributor offers a high efficiency of communication with the IMM control and also allows monitoring and configuration of components directly from the control system.

PRODUCTS USED FOR APPLICATIONS

Systems combined with RENEWABLE ENERGY SOURCES

Usage: Circular Capability On- Grid Off- Grid (4 quadrants).

Used as a test facility for microgrids

Example Features;

2MVA system with 2MW/ 2MWh Li- ion battery

On-Grid with circular capability (4 quadrants)

Ancillary Grid Services; V/f regulation

Combined with an 8MVA wind system

Standard: CEI 0-16

⦁ Virtual Current Generator (CSI)

⦁ Virtual Voltage Generator (VSI)

⦁ CEI- 016 Storage Function

⦁ Stock cabinet (Inverter+ Filter)

⦁ Development of the turn key solution

⦁ Implementation of algorithms for Ancillary Network Services

⦁ (Grid Frequency Regulation/ Grid Voltage Regulation)

Power Optimization

Peak Shaving

Load Shifting

The source must be equipped to be able to generate, transform, and distribute voltage to meet peak demand, whenever the need arises.

The demand charge, i.e., the user’s demand for power, would be reduced through the use of storage systems thus reducing their cost.

DRIVE APPLICATIONS FOR POWER ABOVE 300 KW- UP TO…KW

General data

⦁ Power supply: 400V +-10% – 50Hz +-4%

⦁ Aux voltage: 110V 50Hz- 220V 50Hz- 24V 50Hz- 24V Dc

⦁ Working temperature(stock) from 0°C to 40°C (from -20°C to +60°C)

⦁ Rel. HUMIDITY AND CLIMATE: 80% continental

⦁ Altitude: below 1000m a.s.l

The complete cabinet is equipped with:

⦁ Line input

⦁ Power supply distribution

⦁ Management of the auxiliary services/devices

⦁ Working testing

General and electronic devices:

⦁ Lamps for internal lighting

⦁ Anti-condensation resistor

⦁ Devices for signalling voltage

⦁ Devices for the emergency management according to the standards

⦁ Roof fan

⦁ Selector with line input fuses

⦁ Three phase contractor

⦁ Power switch to the inverter

⦁ Line inductance

⦁ 220V socket

⦁ 400KW INVERTER

⦁ Output inductance

⦁ Auxiliary relays for the sequences management

Cabinet

⦁ n°1 electric cabinet IP23

Cabinet front:

⦁ The front panel is equipped with:

⦁ Main switch circuit braker

⦁ start button

⦁ stop button

⦁ speed adjustment by potentiometer (not by remote control)

⦁ manual/automatic selector

⦁ voltage signalling lamp

POWER RANGE FROM 200 TO 5600 KW (da 380 TO 690V)

Industrial drives have integrated high-performance safety features for safe operation of machines and processes.

The module with PLUG-IN safety features, provides an economical and compact solution that enables higher application productivity.

Liquid-cooled, cabinet-built single drives are ideal for hard conditions.

Often the cabinet will include additional accessories such as contactors and ground fault protection units.

Cabinet drives are typically manufactured to order.

⦁ Fully enclosed cabinet; IP54 as an option.

⦁ Drives built in liquid-cooled cabinet for harsh conditions.

⦁ Customized solutions

⦁ Order based solutions for application engineering

⦁ Industry specific hardware and software solution